Application: Widely used in food, medicine, daily chemical industry of liquid, sauce material packaging.

Type: soy sauce, rice vinegar, fruit juice, beverage, chicken juice, ketchup, chili sauce, bean paste, hot pot base shampoo, body wash, face cream, grease, fat cream, cosmetics, etc.

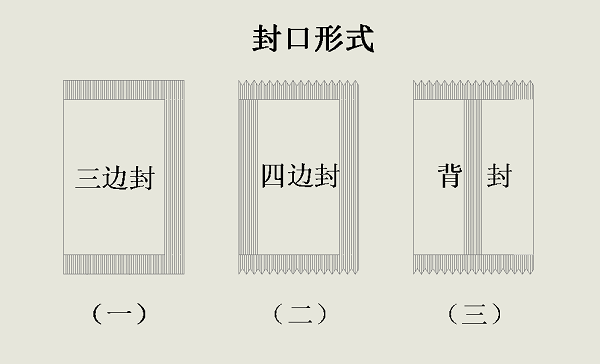

Sealing type: three side sealing, back sealing, four side sealing

Features of this machine:

1. The machine adopts PLC control system, the machine runs smoothly, the action is accurate, the performance is stable, the packaging efficiency is high;

2. Equipment accessories using domestic/international famous brand electrical components, and after years of market practice test, to ensure more stable performance, durable;

3. Stainless steel sheet metal processing and assembly, smooth operation; And the core parts by special optimization design, packaging speed is fast;

4. The pump body material selection of well-known brand manufacturers, stable performance, high efficiency;

5. Optional coding, exhaust, fillet and other systems;

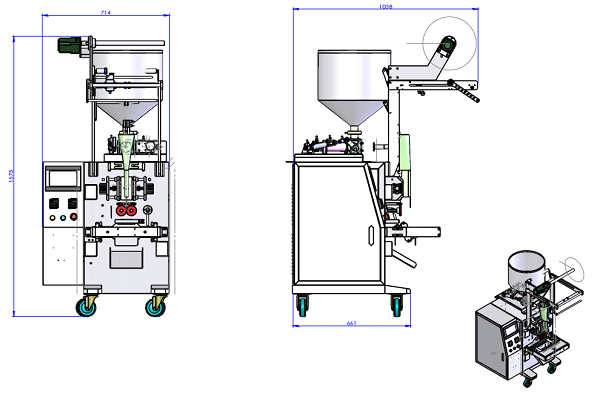

Technical parameters:

Equipment model | MD-300Y | ||||||

Method of measurement | Pump body measurement | ||||||

Production benefit | 30-60 packs/min (depending on material weight) | ||||||

Packing weight | 1-200g (depending on material characteristics) | ||||||

Packing error | ±0.2g (depending on material characteristics) | ||||||

Control system | PLC controller + color touch screen | ||||||

Bag width | 20mm-280mm | ||||||

Bag length | 30mm-170mm | ||||||

Sealing method | Back seal, three sides seal, four sides seal | ||||||

Sealing grain | Stripes, mesh, whiteboards | ||||||

Applicable | PP, PE, PVC, PS, EVA, PET, PVDC+PVC, OPP+ composite CPP, etc | ||||||

Equipment material | Stainless steel (carbon steel) frame, body surface sandblasting and no fingerprint processing | ||||||

Equipment power supply | 220v/50Hz/1.5kw | Gas consumption | 0.5m3/min | ||||

Machine size (L.W.H) | 1050mm*710mm*1620mm | machine weight | 350kg | ||||

selection device | inflator | Exhaust device | Coding machine | Punch fillet | Charging machine | ||

Basic requirements for packaging composite film

1. Food grade polyurethane adhesive

2. Coiling core: Paper coiling core, end face needs to be treated, no crumbs are allowed, reel inner diameter 76-78mm.

3. Tightness: the winding tension is moderate, not too tight, resulting in product stretching; Should not be too loose, resulting in the use of membrane

Slide. When the hand is pushed from the outside to the inside at the section of both ends of the film, no ripple shall be produced.

4. Composite film surface friction coefficient: surface friction coefficient (COF) external ≥0.3 internal ≤ 0.25

5. Low temperature heat sealing means that reliable heat sealing strength can be obtained at low temperature.

6. Choose heat sealing materials with good thermal viscosity, otherwise degumming will lead to bad sealing and air leakage.

7. The diameter of roll film, composite film, composite roll film and aluminum plastic composite film is generally controlled at about 30cm.

8. Perform antistatic operations

9. Thickness 7-9 silk meters

Product details: