Features

1. Independent design of automated structure, through simulation demonstration, analysis and manufacture

2. Equipment parts are processed by high-precision processing equipment

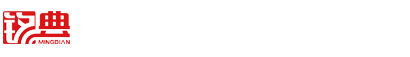

3. Pneumatic components adopt AirTAC, SMC, Festo and other brands

4. The electrical components adopt Siemens, Omron, Schneider and other brands

5. The host and parts are made of 304 stainless steel, aluminum, etc.

6. The material contact part is made of 304 stainless steel.

7. The equipment provides powder or granule vacuum automatic feeding system (for powder and granule)

8. For stacked cup products, the designed multi-layer cup storage mechanism can place multiple layers at one time, automatically replenish the cup, and save labor.

9. Horizontal cup feeding device, manual placement is simple and convenient.

10. For non-stacking cup products, an automatic cup unscrambling device is designed and connected to the storage device. When it is less than the set value, the cup unscrambler will open, and if it is higher than the set value, the cup unscrambler will stop.

11. For products with buckle lids, the lids are automatically sorted and connected to the lid storage device. When it is less than the set value, the lid will be opened, and if it is higher than the set value, the lid will be sorted and stopped.

12. The feeding system adopts a high-precision screw driven by a Siemens servo motor, with an independent anti-drip mechanism to ensure that the weight error of the powder is within ±0.15g.

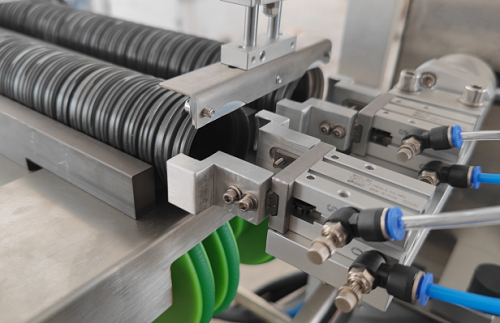

13. Equipment cup edge and cup body cleaning device: self-designed, according to product characteristics, press the inner mouth of the cup, lift the cup away from the mold plate, and carry out strong negative pressure extraction to ensure that there is no residue.

14. The heat-sealing mechanism adopts independent design, and the position can be adjusted independently within 2mm of deviation, and the sealing surface is accurately welded to ensure a beautiful seal and 100% airtight.

15. Nitrogen charging device can be connected

16. Weighing detection and rejection device can be added

17. Multiple groups of material feeding devices can be added

18. Can be connected to subsequent packaging (bags, boxes, barrels, boxes, etc.)

19. Electrical and pneumatic components certification: CE, FDA, UL

20. Gas safety system: When the gas pressure is abnormal, the machine will stop automatically.

21. Moment overload protection device

22. Omron temperature control can be adjusted and set temperature control

23. Set the door to stop

24. Set emergency shutdown